Original Factory Oxygen Making Plant Cost - Medical Air separation equipment – Sihope

Original Factory Oxygen Making Plant Cost - Medical Air separation equipment – Sihope Detail:

Field of application

1. Electric furnace steelmaking: decarbonization, oxygen combustion heating, foam slag, metallurgical control and post-order heating.

2. Wastewater treatment: aerobic aeration of activated sludge, oxygenation of pools and ozone sterilization.

3. Glass melting: Oxygen to help dissolve, cut, increase glass production, and extend the life of the furnace.

4. Pulp bleaching and papermaking: Chlorinated bleaching into oxygen-rich bleaching, providing cheap oxygen, sewage treatment.

5. Non-ferrous metal smelting: Metallurgical steel, zinc, nickel, lead, etc. need to be oxygen-rich, and the PSA method is gradually replacing the deep cold method.

6. Oxygen for petrochemicals and chemicals: Oxygen reactions in petroleum and chemical processes use oxygen rich instead of air for oxidation reactions, which can increase reaction speed and chemical product production.

7. Ore treatment: Used in gold and other production processes to increase the extraction rate of precious metals.

8. Aquaculture: Oxygen-rich aeration can increase the dissolved oxygen in the water, greatly increase the yield of fish, and can deliver oxygen for live fish and intensively raise fish.

9. Fermentation: Oxygen rich instead of air is an aerobic fermentation to provide oxygen, which can greatly improve the efficiency of drinking water.

10. Ozone: Provides oxygen to ozone generators and self-oxygenation sterilization.

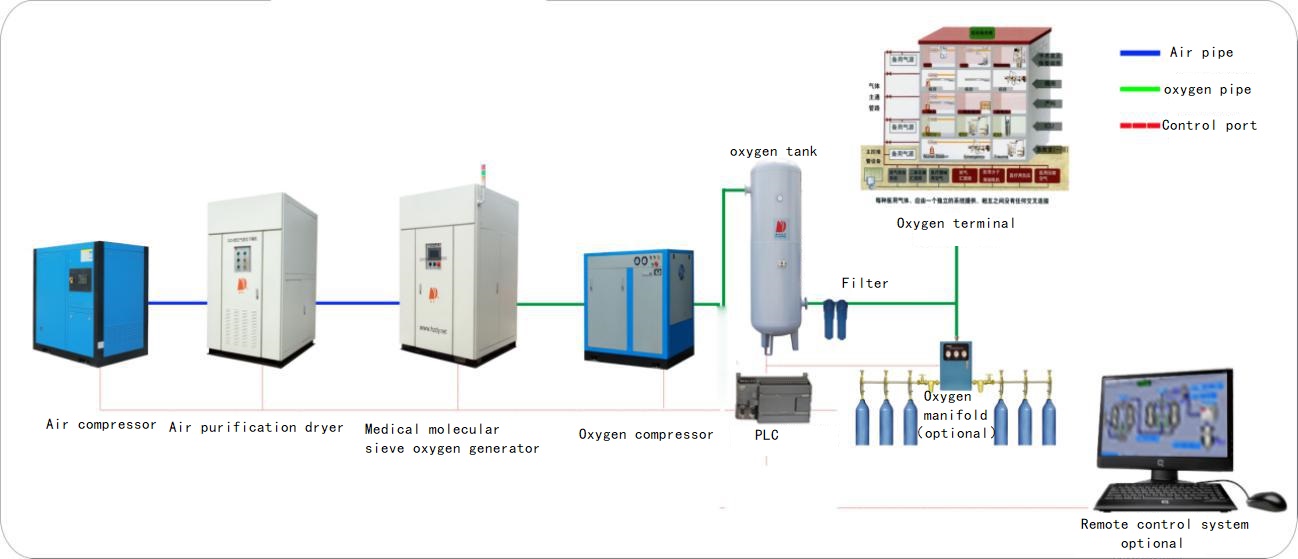

Process flow brief description

Product detail pictures:

Related Product Guide:

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for Original Factory Oxygen Making Plant Cost - Medical Air separation equipment – Sihope , The product will supply to all over the world, such as: St. Petersburg, United States, United Kingdom, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.