New Fashion Design for Oxygen Manufacturing Plant Cost - Gas Solution Oxygen plant for Medical /Industrial (ISO/CE/SGS/ASME) – Sihope

New Fashion Design for Oxygen Manufacturing Plant Cost - Gas Solution Oxygen plant for Medical /Industrial (ISO/CE/SGS/ASME) – Sihope Detail:

1.1 Specification:

1) Purity: 28~95%

2) Capacity: 1~3000Nm3/h

3) Pressure out: 0.1~0.6Mpa (0.6~15.0MPa is also available)

4) Dew point: <-45ºC

5) Type: Skid-Mounted

6)Trademark: Yuanda

7) Origin: Hangzhou, Zhejiang, China

8)Delivery:20-50days

1.2 Product Features

1. Full Automation

All systems are designed for un-attended operation and automatic Oxygen demand adjustment.

2. Lower Space Requirement

The design and Instrumentation makes the plant size very compact, assembly on skids, prefabricated and supplied from factory.

3. Fast Start-up

Start-up time is about 30 minutes to get desired Oxygen purity. So these units can be switched ON & OFF as per Oxygen demand changes.

4. High Reliability

It’s very reliable for continuous and steady operation with constant Oxygen purity. Plant availability time is better than 93% always.

5. Zeolite Molecular Sieves Life

Expected Zeolite Molecular Sieves life is more than 10-years i.e. whole life time of Oxygen plant. So no replacement costs.

6. Low investment and energy consumption

7. Simple operation and maintenance

1.3 Functional Specification:

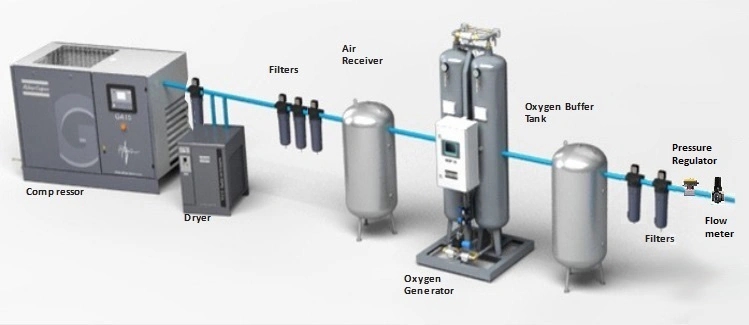

1. The system adopts the one-click start way,Air compressor,Refrigerated Air Dryer, Adsportion dryer,Generator will start to work following the program one by one.

2. The oxygen generator equipped with unqualified oxygen gas warning alarm and automatic vent out ,then it can make sure that all oxygen that goes into the pipeline is good quality.

3. The oxygen generator equipped with colorful touch screen from Siemens Germany ,it can display the running condition , purity, pressure, and nitrogen rate of flow of whole system on-line;And it can also remind the maintenance time,record the trouble alarm, download the operating data.

2. Quality Control

You can be sure of the quality of Sihope solution. Sihope uses only the best suppliers and components. And all nitrogen generators are tested & commissioned by professional Experts to make sure everything is qualified before they leave the factory.

3. Warranty

The period of warranty on the goods from Sihope is 12 months since the completion day of installation and commissioning or 18month after receiving the goods, whichever happens earlier.

4. Service & Support

Sihope offers a range of services to help you maximize your benefits. For maximum convenience, we offer a fixed price service agreement based on operation time or calendar

time. Of course, all customers are welcome to call us at any time. We are always more than willing to assist you.

1) Consultancy

Help for self-help, exchange of experience and individual support.

If you have questions on plant operation or need somebody for troubleshooting, we give you advice either on the phone or in writing. The direct contact with you is very important for us as it is the basis for a permanent cooperation as partners to the benefit of both sides.

2) Commissioning

Systematic from final acceptance of erection to approval of proper operation and guaranteed features. This includes extensive operational tests, professional filling with adsorbents and catalysts, proper start-up, optimal setting of operating parameters and check of all safety functions. At the same time we train your operating personnel on functions and operation of the plant.

3) Spare Parts Service

Worldwide, quick and low-priced over the complete lifetime of your plant. The distinct tagging of all plant components delivered by us enables us to identify clearly the spare parts requested by you. We supply you with products designed for a long life and economic efficiency.

For modifications and extensions we look for the most optimal and economic solution for your individual purpose.

4) Maintenance/Revisions

Regular inspection and maintenance ensures permanent operation, avoids damage and prevents unexpected breakdowns. In the course of maintenance/revision works we check all relevant components for function and condition, exchange defect, used and worn parts and afterwards optimally eadjust your plant to the given operating conditions. Depending on the plant size and

scope of work, our service range comprises also a detailed scheduling of revisions as well as coordination and supervision of contractors. As a matter of course we supply maintenance documentation in form of reports and spare part recommendations, and we coordinate our schedules according to your requirements.

5) Training

Know-how for your personnel.

Operation, maintenance and repair, electric measuring and control equipment or process engineering - we offer you specific training by our experts. Whether on site working with theplant itself, or on our permises, we concentrate on your questions and problems.

5. How to get a prompt quotation?

Do not hesitate to send us mail with the following data.

1) O2 flow rate: _____Nm3/hr

2) O2 purity: _____%

3) O2 discharge pressure: _____Bar

4) Voltages and Frequency: ______V/PH/HZ

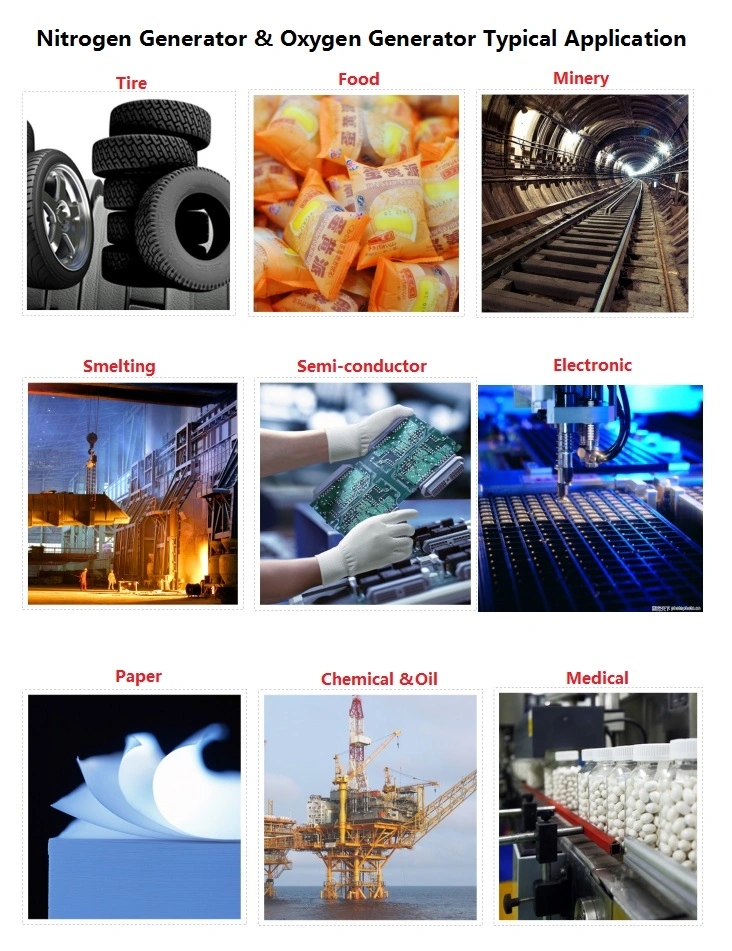

5) O2 Application.

Product detail pictures:

Related Product Guide:

Our company sticks to the principle of "Quality is the life of the company, and reputation is the soul of it" for New Fashion Design for Oxygen Manufacturing Plant Cost - Gas Solution Oxygen plant for Medical /Industrial (ISO/CE/SGS/ASME) – Sihope , The product will supply to all over the world, such as: Czech Republic, Tanzania, Slovakia, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!