Low MOQ for Oxygen Gas Manufacturing Plant - delta p oxygen making machine – Sihope

Low MOQ for Oxygen Gas Manufacturing Plant - delta p oxygen making machine – Sihope Detail:

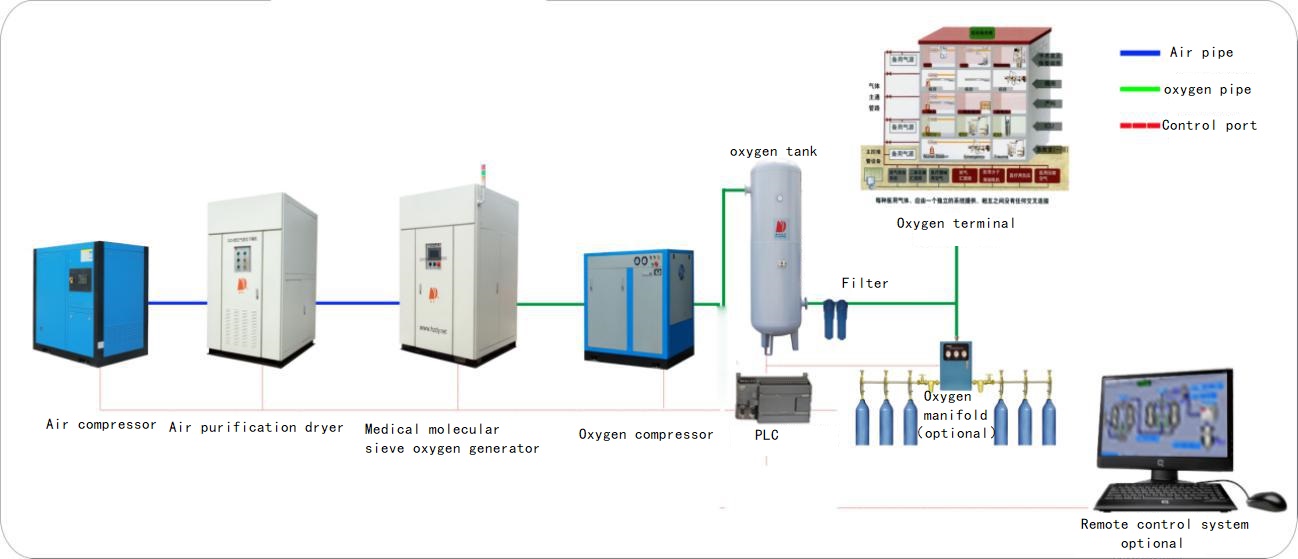

Systems processes

The whole system consists of the following components: compressed air purification components, air storage tanks, oxygen and nitrogen separation devices, oxygen buffer tanks.

1, compressed air purification components

The compressed air provided by the air compressor is first introduced into the compressed air purification assembly. The compressed air is first removed by the pipe filter to remove most of the oil, water, and dust, and then further removed by the frozen dryer to remove water, fine filter to remove oil, and dust. And the depth purification is carried out by the ultra-fine filter immediately following. According to the system working conditions, Chen Rui Company specially designed a set of compressed air remover to prevent the possible infiltration of trace oil, providing adequate protection for molecular sieves. A well-designed air purification component ensures the life of the molecular sieve. Clean air treated with this component can be used for instrument air.

2, air storage tanks

The role of air storage tanks is to reduce the pulse of the air flow and act as a buffer; The pressure fluctuation of the system is reduced, and the compressed air is smoothly purified through the compressed air assembly in order to fully remove oil and water impurities and reduce the load of the subsequent PSA oxygen and nitrogen separation device. At the same time, when the adsorption tower is switched, it also provides the PSA oxygen nitrogen separation device with a large amount of compressed air required for a short period of time to rapidly increase pressure, so that the pressure in the adsorption tower quickly rises to the working pressure, ensuring the reliable and stable operation of the equipment.

3, oxygen nitrogen separation device

There are two A and B adsorption towers equipped with dedicated molecular sieves. When the clean compressed air enters the inlet of Tower A and flows through the molecular sieve to the outlet, N2 is adsorbed by it, and the product oxygen flows out from the outlet of the adsorption tower. After a period of time, the molecular sieve in the A tower was saturated. At this time, Tower A automatically stops adsorption, compressed air flows into Tower B for nitrogen absorption to produce oxygen, and regeneration of Tower A molecular sieve. The regeneration of the molecular sieve is achieved by rapidly reducing the adsorption tower to atmospheric pressure to remove the adsorbed nitrogen. The two towers alternate for adsorption and regeneration, complete oxygen and nitrogen separation, and continuously output oxygen. The above processes are all controlled by programmable program controllers(PLCs). When the oxygen purity of the exhaust end is set, the PLC program functions to automatically empty the valve and automatically empty the unqualified oxygen to ensure that the unqualified oxygen does not flow to the gas point. When the gas is released, the noise is less than 75 dBA by silencer.

4, oxygen buffer tank

Oxygen buffer tanks are used to balance the pressure and purity of oxygen separated from the nitrogen oxygen separation system to ensure continuous supply of oxygen stability. At the same time, after the adsorption tower is switched, it will recharge some of its own gas into the adsorption tower. On the one hand, it will help the adsorption tower to increase pressure, and it will also play a role in protecting the bed layer. It will play a very important role in the process of equipment operation.

Process flow brief description

Delievery

Product detail pictures:

Related Product Guide:

The corporation keeps to the operation concept "scientific management, superior quality and performance primacy, consumer supreme for Low MOQ for Oxygen Gas Manufacturing Plant - delta p oxygen making machine – Sihope , The product will supply to all over the world, such as: French, Italy, Cologne, Our Company has professional engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the products, Please feel free to contact us.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!