Low MOQ for M50 Oxygen Concentrator - Industrial Vpsa Vacuum Pressure Swing Adsorption Oxygen Generator – Sihope

Low MOQ for M50 Oxygen Concentrator - Industrial Vpsa Vacuum Pressure Swing Adsorption Oxygen Generator – Sihope Detail:

While Cryogenic Plants require high capex, VPSA Plants require relatively lower capital. For small capacity requirements, our PSA Oxygen Generator can be used.

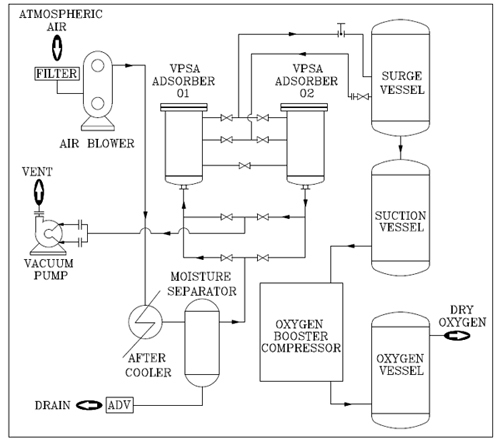

Air from a Blower is first cooled in an Aftercooler to reduce its moisture content and condensed moisture is separated in Moisture Separator. The cooled air passes through a Tower containing an a adsorbent which has the property to separate oxygen from the air resulting in a gas contains 93% oxygen (balance being argon & nitrogen) coming out as product gas. To ensure continuous flow of product gas, the other Tower is simultaneously regenerated by extracting the gases adsorbed in the previous cycle by a Vacuum Pump. Automatic operation is achieved by opening & closing the valves in a preset sequence by using a PLC. Cost of producing this oxygen is < 0.5 KWH at 0.2 bar pressure. There is a small increment in this due to power required for boosting pressure to required value, but this never exceeds 0.6 KWH/NM3. Overall cost of VPSA oxygen is Rs.5/- to 6/- per NM3 as against Rs. 10/- to 15/- for liquid O2.

Major application of this oxygen is for enrichment of combustion air used in fuel fired furnaces & kilns. Since the oxygen is produced onsite, it is a flexible, efficient and cost-effective technology that can help you save costs by lowering fuel usage, improve quality and also reduce emissions. Oxygen enrichment is beneficial in all high temp manufacturing processes used in glass, ferrous & non-ferrous metals, cement, ceramic tiles, sanitary ware, insulators, gasification of coal, coke, biomass, etc.

USES OF OXYGEN

- Oxygen is used to produce Ozone used for different applications (see Uses of Ozone)

- Direct oxygen injection in aerobic fermentation improves productivity of fermentation based pharma products, biofuels & biochemicals

- Using Oxygen for Delignification of Pulp gives significant operating cost advantages enhances yield in bleached pulp production and eliminates use of chlorine based chemicals.

- Oxygen is used as reactant in many chemical oxidation reactions.

- In stainless steel and alloy steel manufacture, decarburization and desulfurization is effectively done by oxygen in conjunction with nitrogen & argon.

- By adding Oxygen to raise the level of dissolved oxygen in Waste water treatment results in reduced odours & increased aeration efficiency.

- Introducing oxygen into metal production operations in BOF, EAF and Cupolas will result in improved productivity, lower costs and reduced CO emission.

- Enriching combustion air with Oxygen in various high temp processes, results in 8 improved productivity, reduced melt times, decreased fuel consumption, increase alternate fuel usage and lower gaseous & particulate emissions.

Some applications include:

- Enrichment of combustion air & oxygen injection in high temp processes.

- Pulp & Paper Industries for oxy bleaching & delignification.

- Chemical Industries for oxidation reactions, fermentation and waste incineration.

- Producing Ozone for treatment of industrial effluents, municipal & domestic waste water.

- Manufacture of caprolactum, acrylonitrile & nitric acid .

- Oxygen for gasification processes.

- Oxygen injection to increase capacity of SRU, FCC & SRM Units in oil refining.

- Glass tube and ampoule manufacture.

Some possible applications are:

- Glass manufacturing.

- Gasification of coal, heavy oils, petroleum coke, biomass, etc.

- Steel re-heating.

- Pig Iron & Steel production in Blast Furnaces, etc.

- Manufacture of Forgings.

- FCC and SRU units of Oil Refineries.

- Melting of aluminium, copper, lead and other non-ferrous metals.

- Hydrogen produced by methane reformer process.

- Cement & lime kilns.

- Production of ceramic, sanitary ware and other clay products.

- Any fuel fired process where temp exceeds 1000.

- Oxygen is used for brazing & soldering in automobile and engineering industries.

- Oxygen is used in manufacture of glass tubes, ampoules, bulbs & other glass products.

- Direct oxygen injection increases capacity in the chemical manufacturing of nitric acid, caprolactam, acrylonitrile, maleic anhydride, etc.

- Oxygen is used in all healthcare facilities for ventilators, etc.

Product detail pictures:

Related Product Guide:

We pursue the management tenet of "Quality is remarkable, Company is supreme, Name is first", and will sincerely create and share success with all clientele for Low MOQ for M50 Oxygen Concentrator - Industrial Vpsa Vacuum Pressure Swing Adsorption Oxygen Generator – Sihope , The product will supply to all over the world, such as: Rio de Janeiro, Sri Lanka, Canada, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we've been committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have now passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.