Excellent quality Psa Oxygen Producing Machine - High Purity 90-96% Industrial and Medical Psa Oxygen Generator with O2 Filling Systems Container Plant – Sihope

Excellent quality Psa Oxygen Producing Machine - High Purity 90-96% Industrial and Medical Psa Oxygen Generator with O2 Filling Systems Container Plant – Sihope Detail:

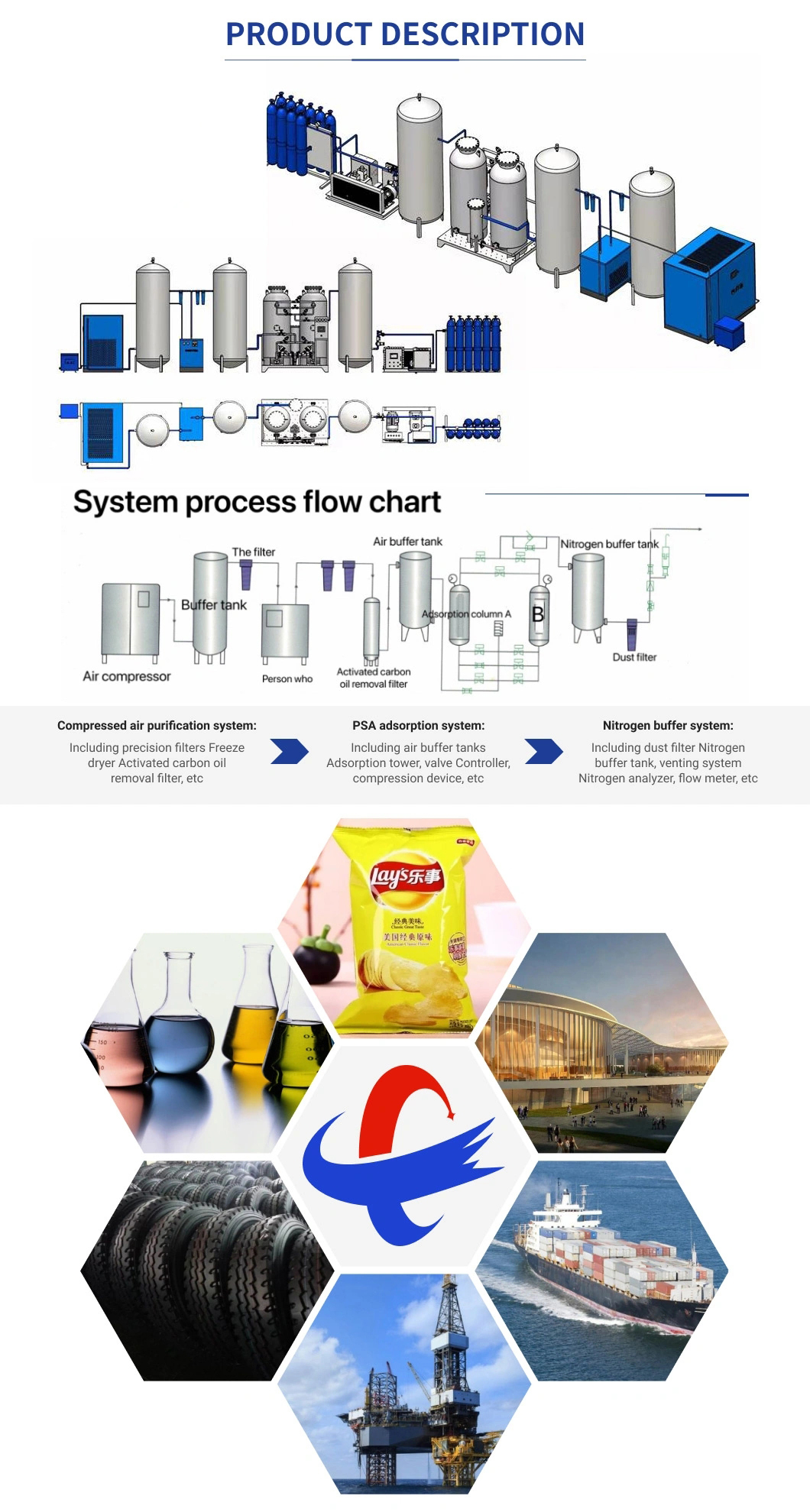

PSA (Pressure Swing Adsorption) is an advanced gas separation technology, based on the physical adsorption of the internal surface in the adsorbent to gas molecules, separating the gas by the characteristics of absorbing to the quantity of different gas in general pressure. The CMS (Carbon Molecular Sieve) is a sorbent picked up from the air, used in separating Oxygen and Nitrogen molecular. The absorption quantity of CMS is greatly higher for Oxygen than Nitrogen under the same pressure.

Oxygen generator Feature

1.Unique CMS safeguard are used to lengthen the life of CMS;

2.Nitrogen chain liberated air automatic system is used to guarantee the quality of nitrogen;

3.Air Cylinder Pressure are used to avoid CMS chalking by the high speed air impact;

4.Reasonable structural design are make sure the transport, lifting and installation easier;

5.Easy to use, plug and play.

Oxygen generator of production equipment

Bevelling machine

Bending roll

Automatic welding machine

Automatic casing cutter

Automatic arc-submerging welder

Oxygen generator Performance guarantee and after-sale service

All equipment in the contract be designed and manufactured in accordance with current Chinese & professional standard and regulations;

Warranty period: 12 months after formal running or 18 months after delivery, whichever occurs first;

Afterwards, prompt maintenance service and spare parts will be available with charge.

Documents and drawings provided by the seller shall be drawn in English version.

Oxygen generator QA

1. What is the difference between a VPSA oxygen generator and a PSA oxygen generator?

The PSA oxygen generator is suitable for use under 300 cubic meters and has the characteristics of simple and convenient, movable.

VPSA oxygen generator is suitable for more than 300 cubic meters of use, the greater the gas volume, the lower the energy consumption.

2. What is the difference between a fish pond aerator and a fish pond oxygen generator?

The aerator is a self-contained air pump that mixes 20% of the oxygen in the air into the water.

The oxygen generator is dissolved in water by producing 90% pure oxygen.

Merchants need to consider the choice of aerobics or oxygen generators based on the type of fry, increasing the oxygen production rate to increase the production cycle, and the total ratio of fish ponds.

3. What is the purity of the PSA oxygen generator?

The purity of the general PSA oxygen generator is 90%-93%.

Our company’s PSA oxygen generator can reach 95%, 98%, up to 99+%.

4. What should I pay attention to when using the oxygen generator for ozone?

Ozone supporting oxygen generators mainly need to select an oxygen generator with stable gas volume and purity to avoid ozone concentration and production due to instability.

5. How to maintain the PSA oxygen generator

The daily maintenance of the oxygen generator is relatively simple:

(1) The air compressor should be regularly maintained, air filter, oil, and oil should be replaced by the manufacturer at regular intervals according to the instructions.

(2) The dryer should regularly check the pressure of the refrigerant to make it timely. The heat sink should be cleaned with compressed air every day. The filter element should be replaced regularly. The normal temperature is 8000H. It depends on the specific situation and pressure difference.

(3) Open the air storage tank drain once a day and drain the condensate from the air.

(4) Check the automatic drainer daily to avoid clogging and lose drainage. If it is blocked, open the manual valve slightly, close the self-discharge valve and then remove the automatic drainer to disassemble and clean. When cleaning the automatic drain, use soap to clean.

(5) The oxygen generator mainly checks the working pressure of the adsorption tower, and records the purity and flow rate.

Product detail pictures:

Related Product Guide:

We always stick to the principle "Quality First, Prestige Supreme". We are fully committed to providing our clients with competitively priced quality products, prompt delivery and professional service for Excellent quality Psa Oxygen Producing Machine - High Purity 90-96% Industrial and Medical Psa Oxygen Generator with O2 Filling Systems Container Plant – Sihope , The product will supply to all over the world, such as: Albania, Serbia, Lisbon, Custom orders are acceptable with different quality grade and customer's especial design. We are looking forward to establish the good and successful cooperation in business with long terms from the customers of all over the world.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!