2021 Latest Design Cryogenic Oxygen Plant - Medical Psa Oxygen Gas Generator Making Machine 3Nm3 / H To 200Nm3 / H Purity 93% – Sihope

2021 Latest Design Cryogenic Oxygen Plant - Medical Psa Oxygen Gas Generator Making Machine 3Nm3 / H To 200Nm3 / H Purity 93% – Sihope Detail:

Sihope On-Site Oxygen Generators are a cost-effective alternative to purchasing cylinder oxygen from industrial gas suppliers. By producing your own oxygen gas, at your facility, you can save up to 80% of traditional gas contract prices. Sihope has a large selection of standard configurations to assure you find the right product to fit your exact needs.

Sihope offers two different types of Oxygen Generators. Each type of Oxygen Generator has unique properties designed for a specific market application. Several options are available to easily customize a unit for your exact application. If you need any assistance in the selection process, one of our On-Site specialists will be happy to assist you. Each Technology has unique attributes based on its operating principle; in general, however, the technologies can be grouped into Low Pressure or High-Pressure designs. The highest cost of operating these systems is the cost of power. By selecting the appropriate product desired pressure, the cost of the product can be optimized for each application.

Oxygen Generators

-

- Sihope utilizes two technologies that produce oxygen up to 95% Purity Oxygen

- Traditional twin tower PSA Technology – Produces oxygen at 80-100 PSIG. This technology is utilized for most industrial applications

- VPSA Technology – This technology produces large quantities of Oxygen at low pressure 4-5 PSIG. This technology is used in low pressure application such as waste-water treatment, fish farming, Oxygen-Enriched Oxy-Fuel Combustion, Gasification Processes (VPSA Technology), etc.

- Both Technologies offer an endless supply of oxygen for a wide range of commercial applications.

- High purity Oxygen Generator with purities to 99%.

- These systems consist of two stages of purification. The first stage is a traditional Oxygen PSA. The produced 95% oxygen from the first stage is then fed into a second PSA which removes Argon and residual Nitrogen to achieve the 99% Oxygen Purity

- Sihope utilizes two technologies that produce oxygen up to 95% Purity Oxygen

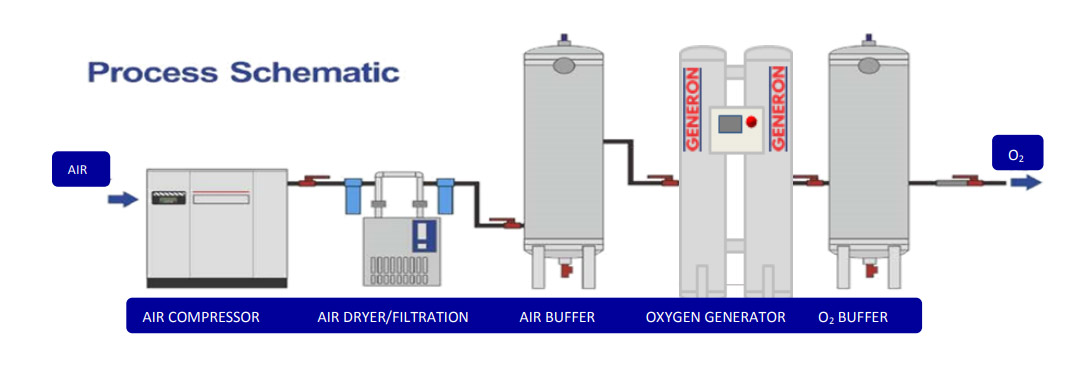

All of the Sihope systems can be packaged on a skid or installed into a containerized system with all ancillary equipment included – Compressors, Dryers, Filtration, and high-pressure bottle filling stations.

The PSA Technology produces Oxygen from 65 SCFH (1.71 Nm3/hr) to 5000 SCFH (132 Nm3/hr) at 80-100 psig.

The VPSA Technology produces Oxygen from 7 tons/day (190 Nm3/hr) to 34 tons/day (1,000 Nm3/hr) at 3-5 psig.

Need help deciding which generator is right for a particular application? One of our product Specialists can help you, based on your final product pressure, and flow requirements

-

- Metal Cutting (PSA)

- Fish Farming (VPSA Technology)

- Waste Water Treatment (VPSA Technology)

- Mining (PSA)

- Labs (Single and Two Stage PSAs)

- Oxygen-Enriched Oxy-Fuel Combustion (VPSA Technology)

- Gasification Processes (VPSA Technology)

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new merchandise into the market each and every year for 2021 Latest Design Cryogenic Oxygen Plant - Medical Psa Oxygen Gas Generator Making Machine 3Nm3 / H To 200Nm3 / H Purity 93% – Sihope , The product will supply to all over the world, such as: Nepal, Palestine, Belgium, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we are going to continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!