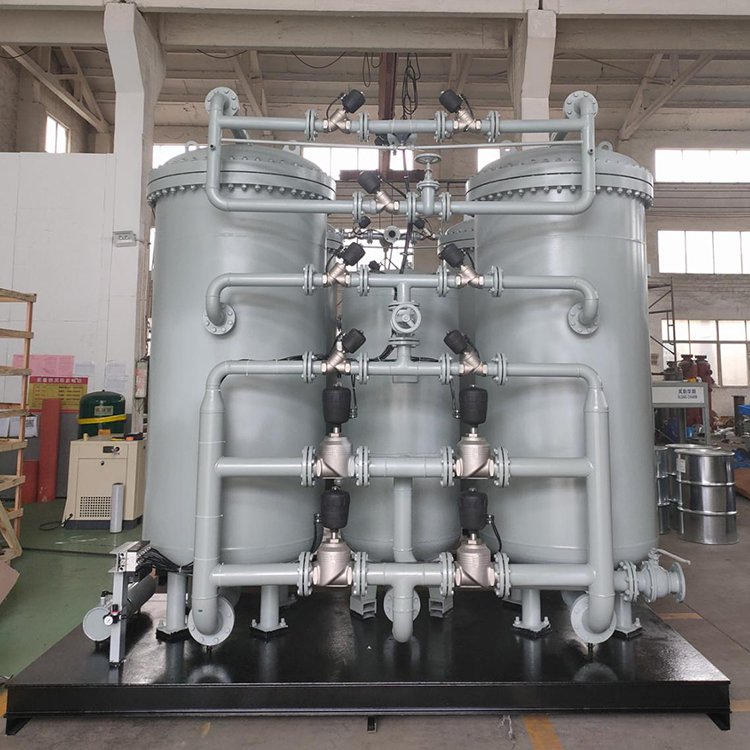

100% Original High Purity Nitrogen Generator - Air Separation Machine Split Type Psa Industrial Nitrogen Generator with High Output Multi Models – Sihope

100% Original High Purity Nitrogen Generator - Air Separation Machine Split Type Psa Industrial Nitrogen Generator with High Output Multi Models – Sihope Detail:

Nitrogen is presently being used in a broad spectrum of industries, laboratories, tank farms, mines, etc. In most applications, the N2 pressure required is less than 6 bar. Despite this, high pressure N2 cylinders are commonly used as source of N2, whose handling is quite hazardous & risky. A better option would be to produce your own low pressure N2 by installing our Nitrogen Generator.

How do I produce my own N2 ?

Low pressure N2 can be produced by separating oxygen and nitrogen in air by using the Pressure Swing adsorption (PSA) process. Dry, oil-free compressed air at around 7.5 bar pressure enter the PSA System where the oxygen is adsorbed by the Carbon Molecular Sieves and pure nitrogen comes out as a product gas. The N2 (pressure of around 6 bar) is stored in a Receiver and drawn for use, whenever required. Necessary measurement and control devices are incorporated to make the N2 Generator fully automatic as well as to ensure that only pure N2 goes to your User equipment.

What are the benefits of producing your own N2 ?

(a) You save money – N2 from Generator costs 30% to 50% of N2 from cylinder. Payback periods are generally less than one year, which can reduce further if you have compressed air already available in your mfg facility. (b) It gives N2 of better and consistent purity than that available from cylinders where O2 content can vary from 0.5% to 4% (based on actual measurements taken by us). In our Generator, continuous online O2 measurement is available. (c) Elimination of risk of accidents which may take place due to handling of N2 cylinders as well as due to excess O2 in cylinders.

Some applications include:

- Inert gas purging & blanketing

- Food packaging

- In Air Jet Mills & Fluid Bed Dryers,

- Analytical Instruments

- Molten metal degassing

- Heat treatment

- Pipeline cleaning

- Fire fighting

- Tyre filling

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for 100% Original High Purity Nitrogen Generator - Air Separation Machine Split Type Psa Industrial Nitrogen Generator with High Output Multi Models – Sihope , The product will supply to all over the world, such as: Israel, Muscat, Marseille, We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.